QUALITY, PRECISION AND SPEED

FABRICATION

CNC controlled, automated fabrication equipment means reliable, reproducable results in raw material fabrication. From design drawings to cutting and forming, tolerances are predictable. That means the right fit for our customers – every time.

ASSEMBLY

Raw materials like steel, aluminum, copper and brass are combined to form the base of our products.

EXPANSION

Copper tubes are mechanically bonded to the fins, that’s where heat transfer takes place.

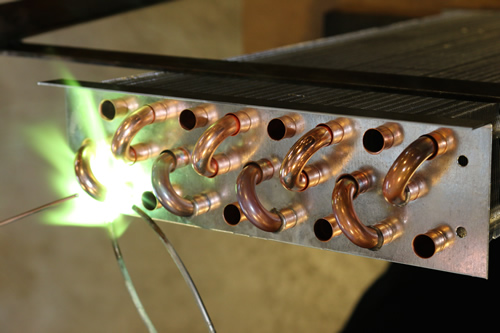

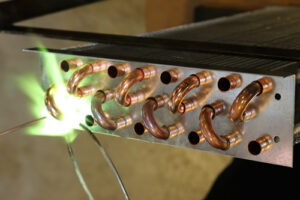

BRAZING

During the brazing process, we put the finishing touches on our coils to ensure the system is complete.

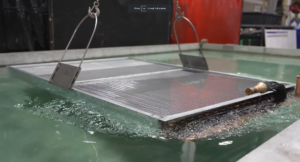

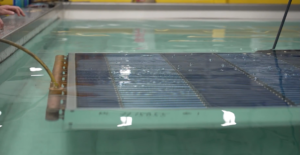

TESTING

When a coil is immersed into one of our testing tanks, we charge it to between 325 – 600 psi of compressed air or nitrogen and test to ensure that the product is leak-free. The charge pressure is determined by the application and certification of the coil.

PACKAGING & SHIPPING

Every coil that we build is specific to a customer, so we place products on fitted custom skids or specific boxes so the coil arrives at your door in mint condition. We constantly keep our environment in mind – so we’ve eliminated packaging materials that cannot be easily recycled at customer facilities or in the field. We can ship internationally and domestically.